WHAT IS STAINLESS STEEL USED FOR? | Fabrinox

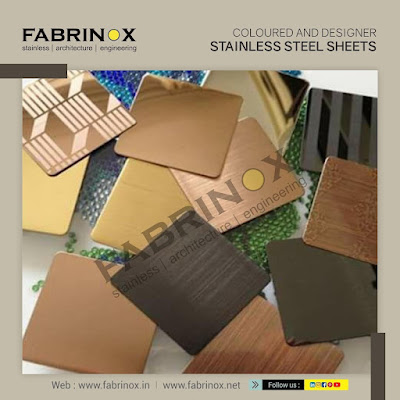

Stainless Steel sheet is one of the most versatile metals available. It is durable, has high tensile strength, is affordable, and is comparatively easy to work with. It is a steel alloy containing at least 10.6% chromium, which gives the stainless steel its anti-corrosion and anti-staining properties. The stainless-steel sheet is only ¼ inch thick. If it gets thicker than that, it's called a "plate." Stainless steel sheet comes in many variations, each with different advantages and disadvantages. Ferritic, duplex, 200 Series Austenitic, and 300 Series Austenitic are a few types of stainless steel sheets . Stainless steel can be used in products, from electronic to high-range industrial applications. Working with this metal is relatively easy, but it depends on why you use it. It can be cut, bent, or welded, but each requires different precautions and heating temperatures, and the sheet is thin. USES OF STAINLESS STEEL SHEET: - PVD Colour Stainless steel sheets ca...